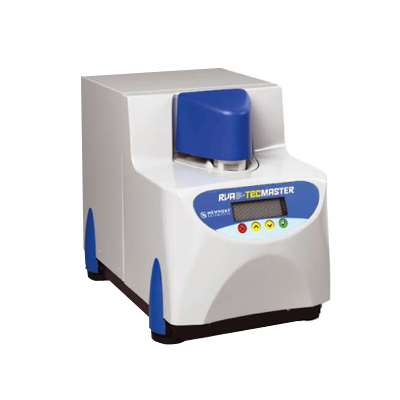

Rapid Visco Analyser

The Rapid Visco Analyser is a unique tool for product development, quality and process control and quality assurance.

The RVA is a cooking, stirring viscometer with ramped temperature and variable shear capability optimized for testing the viscous properties of starch, grain, flour and foods. The instrument will analyze as little as two or three grams of sample using international standard methods or your own tailor-made test routines of mixing, measuring, heating and cooling.

Applications include: flour and grain quality, native starches, modified starches and starchy samples, formulated foods (e.g. sauce, ketchup, gravy, dressing, mayonnaise, soup, dairy beverages) other ingredients and foods (e.g. hydrocolloids & proteins), cooked and extruded foods (e.g. ready to eat breakfast cereals, snack foods, pet foods, fish feeds and animal feeds), meltability tests (e.g. process cheese, chocolate and confectionery) and “Miniature Pilot Plant” small scale process emulation.

Features and benefits - RVA viscometers

Rapid Visco Analyser:

Viscosity Range to suit your samples: Mid viscosity range for most samples (RVA-TecMaster), extended range for high viscosity combined with high sensitivity for low viscosity (RVA 4500), and mid range with four preconfigured methods for routine samples (RVA-StarchMaster2).

Rapid Viscosity Profile: Standard starch pasting test in 13 minutes.

Easy to Use: Automated operation of RVA 4500 and RVA-TecMaster using Thermocline for Windows (TCW) minimizes training and ensures reliability.

Stand-alone option: Preconfigured RVA-StarchMaster2 operates simply; no computer required; no software to learn.

Calibration: Check with traceable standards to comply with ISO9000 and Quality System requirements.

Glass-free: Safe for food manufacturing areas.

Relevant: Tailor test routines to emulate processing conditions in industry.

Thermocline for Windows (TCW) Software:

Programmable Instrument Control: “Profile” style method set up with advanced options and auto functions

for flexibility and ease of use.

Flexible Data Analysis: Auto functions for commonly derived parameters and advanced functions for research.

Real Time Graph Display: Interactive and overlay functions for clarity.

Single Page Report: Traceability data, results and the graph all on a single page.

Traceability: Complies with ER/ES (electronic records/electronic signatures) requirements for data security.

Applications for RVA Viscometers

The RVA is ideal for fingerprinting the viscosity, hydration and degree of cook of wide range of products. If your application is not listed below, click on “Industries” in the menu bar and link to your industry for more applications information. Still can’t find what you are looking for? Click on “Ask us a question” below.

•Starches and Starchy Samples:

Native and modified starches of grains, roots, tubers and others.

•Hydrocolloids:

Gelling/thickening profile, hydration profile, preparation of samples that will gel.

•Proteins:

Soy products, milk proteins, gluten, gelatin and egg whites.

•Milling and Baking:

Grain soundness and bug damage, starch pasting quality for cakes, breads, batters, pasta and noodles, flour amylase, malt amylase, fungal amylase, anti-staling, heat treatment of flour, wheat gluten quality and solvent retention capacity test.

•Barley – Malting – Brewing:

Predicting safe storage life for malting barley, rapid recording mashing system (and the effect of addition of enzymes, adjuncts and chemicals to malts), monitoring the progression of malting, predicting barley malting quality and simulated industrial mashing process.

•Dairy:

Process cheese manufacture and meltability, effect of drying temperature on milk protein powders, rennet caseinate rehydration, dairy beverages, custard, age thickening of sweetened condensed milk and “Miniature Pilot Plant” small scale manufacture of yoghurt, ice cream mix and dairy desserts.

•Formulated foods:

Low viscosity products (premixes & ready to use) such as sauce, ketchup, gravy, dressing, mayonnaise, soup, other low viscosity foods with starches, hydrocolloids & proteins, melt tests such as chocolate and confectionery and “Miniature Pilot Plant” small scale emulation of manufacturing conditions.

•Extruded and Cooked Foods:

Ready to eat breakfast cereals, snack foods, pet foods, aqua feeds and animal feeds.

|